Submit

Submit feedback

COMPANY PROFILE

China international motorcycles/cars vehicles bearings manufacturers and wholesale standards & non-standard hardware suppliers

, At the core of our services are ODM/OEM offerings, where we balance cost-effectiveness with stringent quality control. Leveraging years of industry experience and robust customization capabilities, we can offer you professional solutions tailored to your specific needs.01

10 YEARS INDUSTRY EXPERIENCE

02

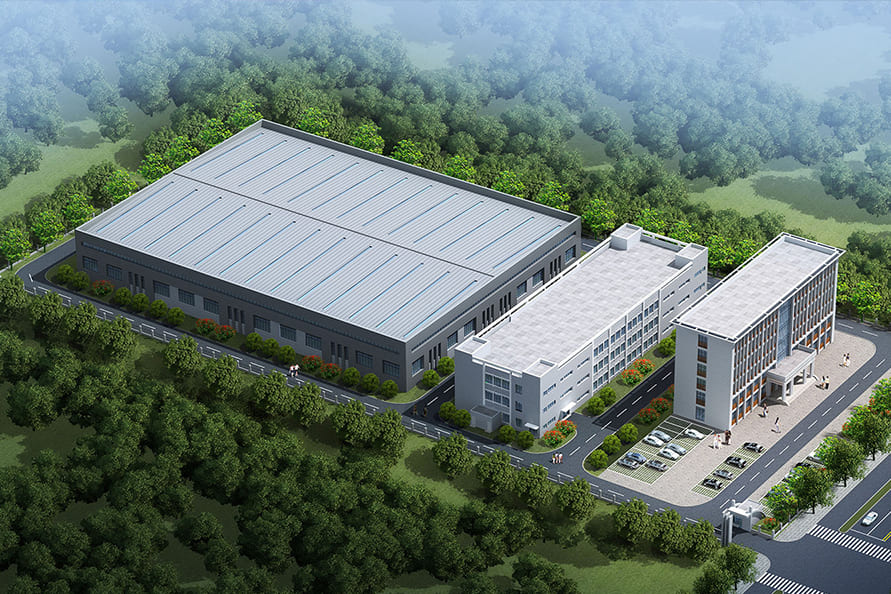

8700m² advanced factory

03

15 high-tech professionals

04

Annual production: 2.4 million sets

-

Reasons to choose YINGFEI

We are an enterprise that combines industry and trade, primarily engaged in the manufacturing and trade of deep groove ball bearings, miniature bearings, fasteners, and other hardware products. We offer customized solutions tailored to the market and the specific needs of our customers. Despite variations in the market, applications, and customer requirements, Yingfei has a unique philosophy to guide our customers toward success.

Technical team support

We have a skilled and experienced team dedicated to providing comprehensive technical support and customized solutions to meet the diverse needs of our customers.

-

Customization

We provide professional OEM and ODM services, committed to meeting the personalized needs of customers and ensuring that each customized service can accurately meet the expectations of customers.

Strict quality control

Our products are certified by ISO 9001:2015 international quality system to ensure that every product strictly follows high quality standards and provides customers with great quality assurance.

-

Advanced production capabilities

We have a modern factory covering 8,700 square meters, with an annual output of 2.4 million sets, meeting the market demand with efficient production capacity.

-

01

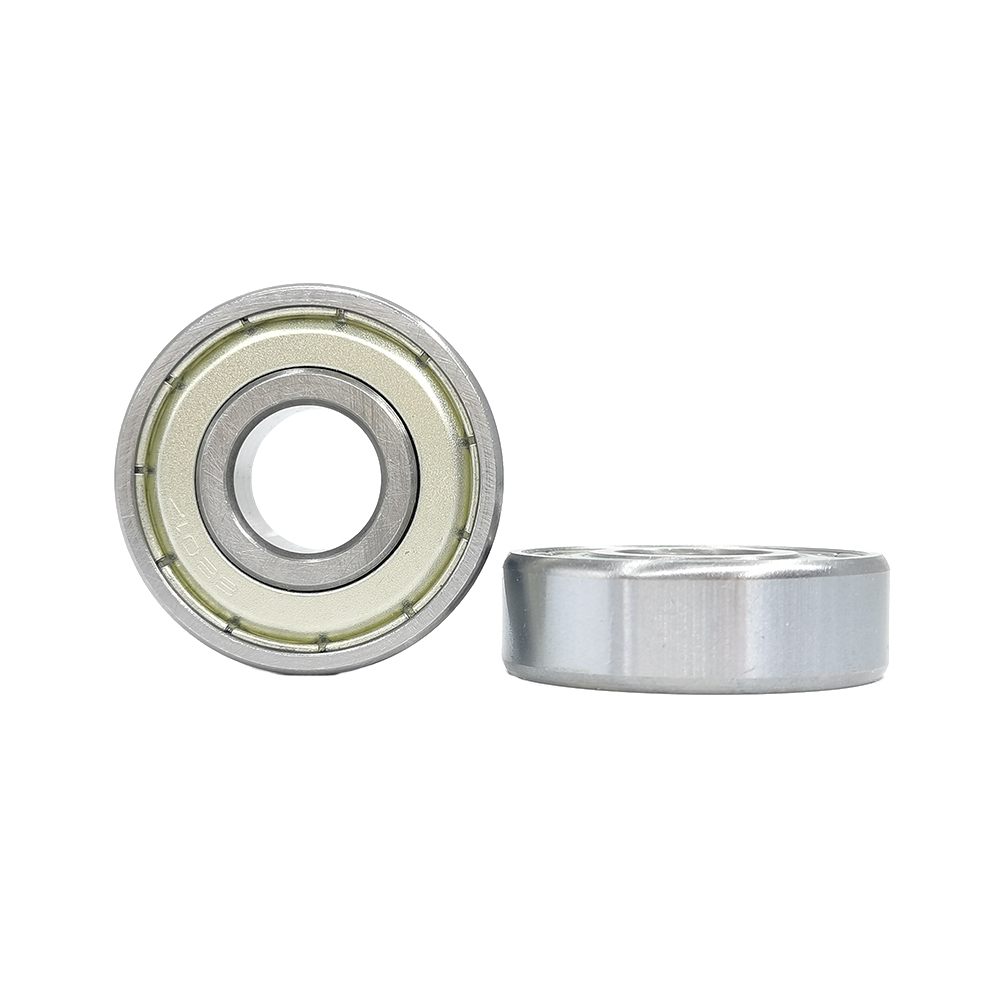

Deep Groove Ball Bearings

Deep groove ball bearings consist of an outer ring, an inner ring, steel balls, and a retainer. They are typically made of bearing steel, which is known for its high hardness and wear resistance. Thes...

-

02

Stainless Steel Bearings

Stainless steel bearings consist of an outer ring, an inner ring, and a set of retainers. They offer excellent rust and corrosion resistance, typically made from materials like AISI 440C, and undergo ...

-

03

Plastic Coated BS Bearings

Plastic coated bearings are coated with plastic to enhance wear resistance, impact resistance, and self-lubricating performance. Commonly used plastics include nylon PA, ABS, polyoxymethylene POM, and...

-

04

Polyurethane PU Bearings

Polyurethane bearings, made from polyurethane materials, offer excellent elasticity, wear resistance, corrosion resistance, and high-temperature performance. These bearings can effectively reduce fric...

-

05

Flange Bearings

Flanged bearings are rolling bearings equipped with a flange, facilitating installation and fixation. They typically consist of an inner ring, an outer ring, rolling elements, and a retainer. These be...

-

-

07

Fastener

Fasteners are mechanical parts used for joining or securing structural components, including bolts, nuts, screws, and washers, among others. They are typically made from materials such as carbon steel...

recommend products

-

608RS Chrome steel Double Rubber Sealed Deep Groove Ball Bearings

-

608ZZ Single column Double Iron Sealed Deep Groove Ball Bearing

-

6000RS Carbon steel Double Rubber Sealed Deep Groove Ball Bearings

-

6000ZZ Grease Lubrication Double Iron Sealed Deep Groove Ball Bearing

-

6001RS Double Rubber Sealed Deep Groove Ball Bearings For Motorcycles

-

6001ZZ Oil Lubrication Double Iron Sealed Deep Groove Ball Bearing

-

6201RS Double Rubber Sealed Deep Groove Ball Bearings For Cars

-

6201ZZ Single Column Double Iron Sealed Deep Groove Ball Bearing

-

604RS 11kgs Double Rubber Sealed Deep Groove Ball Bearings

-

604ZZ Carbon Steel Double Iron Sealed Deep Groove Ball Bearing

-

606Z Double Iron Sealed Deep Groove Ball Bearing For Appliances

-

623RS Chrome steel Double Rubber Sealed Deep Groove Ball Bearings

Application Areas

Our bearing products are widely used across a variety of industries, including motors, home appliances, automobiles, mechanical equipment, sports equipment, furniture, baby strollers, and more, to meet the diverse needs of our customers.

0

0